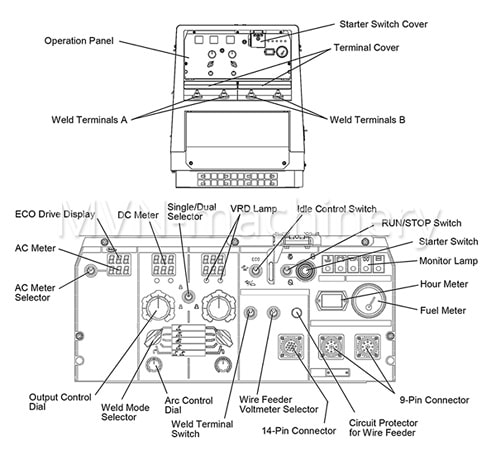

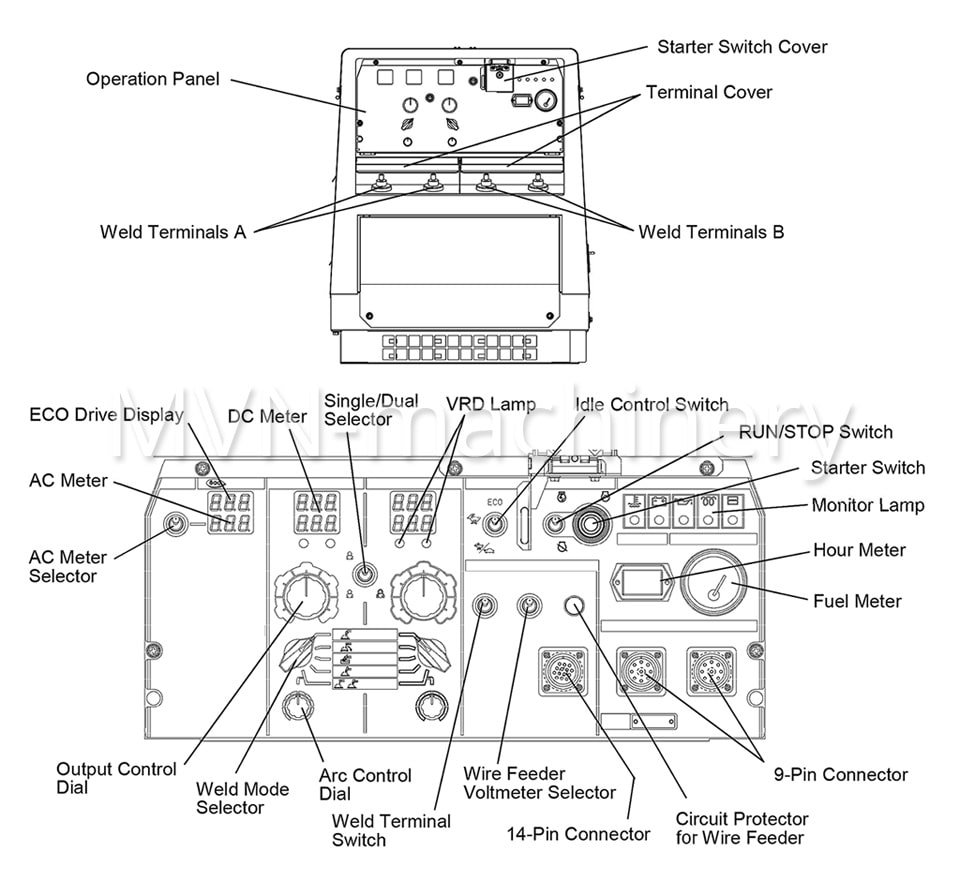

Diesel welder control panel - elements and monitoring devices

The control panel of Shindaiwa diesel welder is thoughtfully designed to provide welders with easy access to essential functions and settings. It offers a user-friendlyinterface that enables precise control and monitoring of the welding process.

List of typical functions, instruments and indicators of the control panel Shindaiwa welder:

- ECO Mode Display.The equipment includes an eco drive function in order to reduce noise, save fuel, and reduce exhaust gas emission;

- AC Meter.The control panel includes an AC meter that provides digital display of voltage, current and frequency of three phase 240V generated output;

- AC Meter Selector. The AC meter is equipped with an AC meter selector that can be switched to display voltage, current or frequency;

- DC Meter & VRD Lamp. The equipment includes a DC meter that provides digital display of both weld current and voltage. The DC ammeter and voltmeter display the weld output for both outputs A and B separately. The diesel welder control panel a voltage reduction device on the weld output side. The voltage reduction device increase safety when welding in locations with high humidity, elevated locations, extremely confined spaces near possible hazards, and similar conditions;

- Idle Control Switch. The equipment includes an idle control function to select an engine speed setting of "ECO", "AUTO" or "HIGH";

- Starter Switch to starts the engine;

- Monitor Lamp. To enhance safety and troubleshooting, the control panel may include error indicators or alarms that alert the operator to potential issues. These can include indicators for overheating, oil pressure and spill containment, battery charge faulty;

- Single/Dual operator mode Selector;

- Hour Meter - Equipment operating time counter;

- Fuel Meter - Fuel tank level indicator;

- Output Control Dial. Current or voltage adjustment knobs separately for each welding terminal;

- Emergency Stop Switch. Emergency stop switch to stop the engine immediately;

- Weld Mode Selector. Select a weld mode of "CV-WIRE", "DROOP-STICK", "GOUGING", "LIFT START TIG" or "CC-STICK" in accordance with the type of welding being performed;

- Arc Control Dial. The Arc control function that adjusts the arc strength and setting of the short-circuit current of the weld output by turning the arc control dial;

- Remote Control Receptacles. Sockets for connection a compatible remote controller to the 9-pin connector to enable remote operation of weld output adjustment;

- , 17 Weld Terminals A & B - welding cables connections;

- Circuit Protector. The circuit protector for the wire feeder operates to stop the current if the there is an overcurrent of 5A or more in the wire feeder fault;

- Wire Feeder Voltmeter Selector. Select the polarity of the voltmeter display equipped to the wire feeder;

- Weld terminals switch. Voltage is constantly output "ON" or when the torch switch is "ON" only.