Specific Technological Properties of the DGW400DMK Engine Driven Welder

Balanced volt-ampere characteristics (VAC) allow welding in all spatial positions over a wide range of modes. Reliable arc ignition and stable burning are ensured by the open-circuit voltage of 85 V when welding with electrodes, regardless of the coating type, and with long and short arcs.

Thyristor welding rectifier The electrical circuits of the DGW400DMK Engine Driven Welder use IGBT transistors, providing good responsiveness and low switching losses with optimal saturation depth. The presence of a thyristor rectifier increases efficiency and reduces maintenance costs.

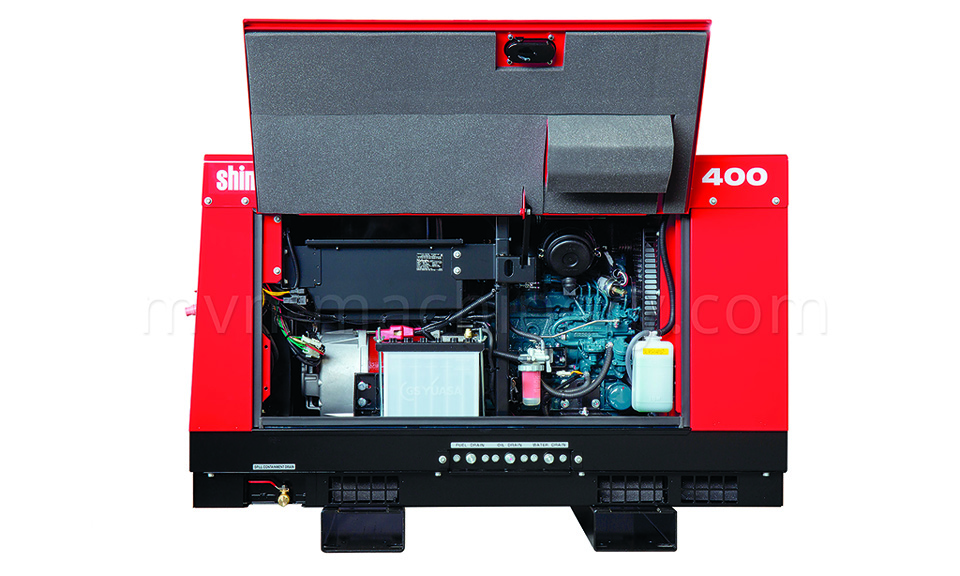

Reliability and safety The power Engine Driven Welder of the unit is based on the Kubota D902 diesel engine. The reliable and economical Kubota engine ensures stable operation of the unit under increased load and in harsh operating conditions. The Engine Driven Welder's operation safety is guaranteed by unique emergency systems:

- Overheat protection;

- Emergency signaling;

- Emergency shutdown in case of overloads;

- Protection against electric shock, including grounding terminals.

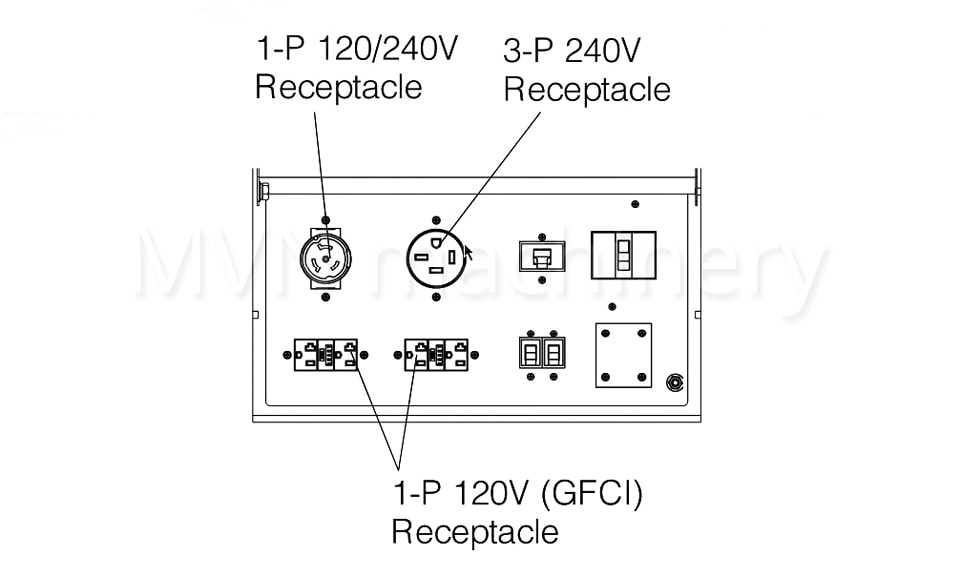

Informative control panel The control panel of the DGW400DMK Engine Driven Welder has indicators and displays reflecting the current welding mode and equipment operating parameters, as well as controllers, switches, and control buttons.